The Importance of an Oil Catch Can

Published by John on 23rd Mar 2021

There are many systems at play in the modern diesel engine, and a few of these are focused on reducing emissions.

Most modern diesel engines utilise Exhaust Gas Recirculation (EGR) or a Diesel Particulate Filter (DPF) to reduce emissions such as nitrous oxide and soot in the exhaust.

This, together with new diesel engine technologies like common rail, can choke your engine intake. Accessories like an oil mist filter or catch can are designed to help combat some of the issues.

What is an Oil Catch Can?

On modern 4wds, primarily turbo-diesels models, small quantities of gas from the combustion process in the engine trickles past the piston rings and into the sump.

Crankcase ventilation stops this pressure from growing by releasing it on older 4wds straight into the atmosphere, whilst on newer 4x4 vehicles it is recirculated into the air intake to be burned in the cylinders.

This air is heavily laden with oil mist, precisely the kind of thing that we don't need hovering in the air we inhale, nor in the air our engines want to breathe.

A catch can's main job is to separate the oil from the air so the oil can be stored and either disposed of periodically or fed back into the sump where it can continue to lubricate your engine.

They are a passive device that won't alter your engine's fuel economy or performance directly and isn't an illegal modification.

Instead, a catch can will reduce maintenance costs and minimise any potential issues.

This video explains the oil catch can process:

Credits: Engineering Explained

Why would you need one for your 4wd?

Late model turbo-diesel engines are filled with an array of sensors, valves, filters and pipes required to keep them running safely and efficiently.

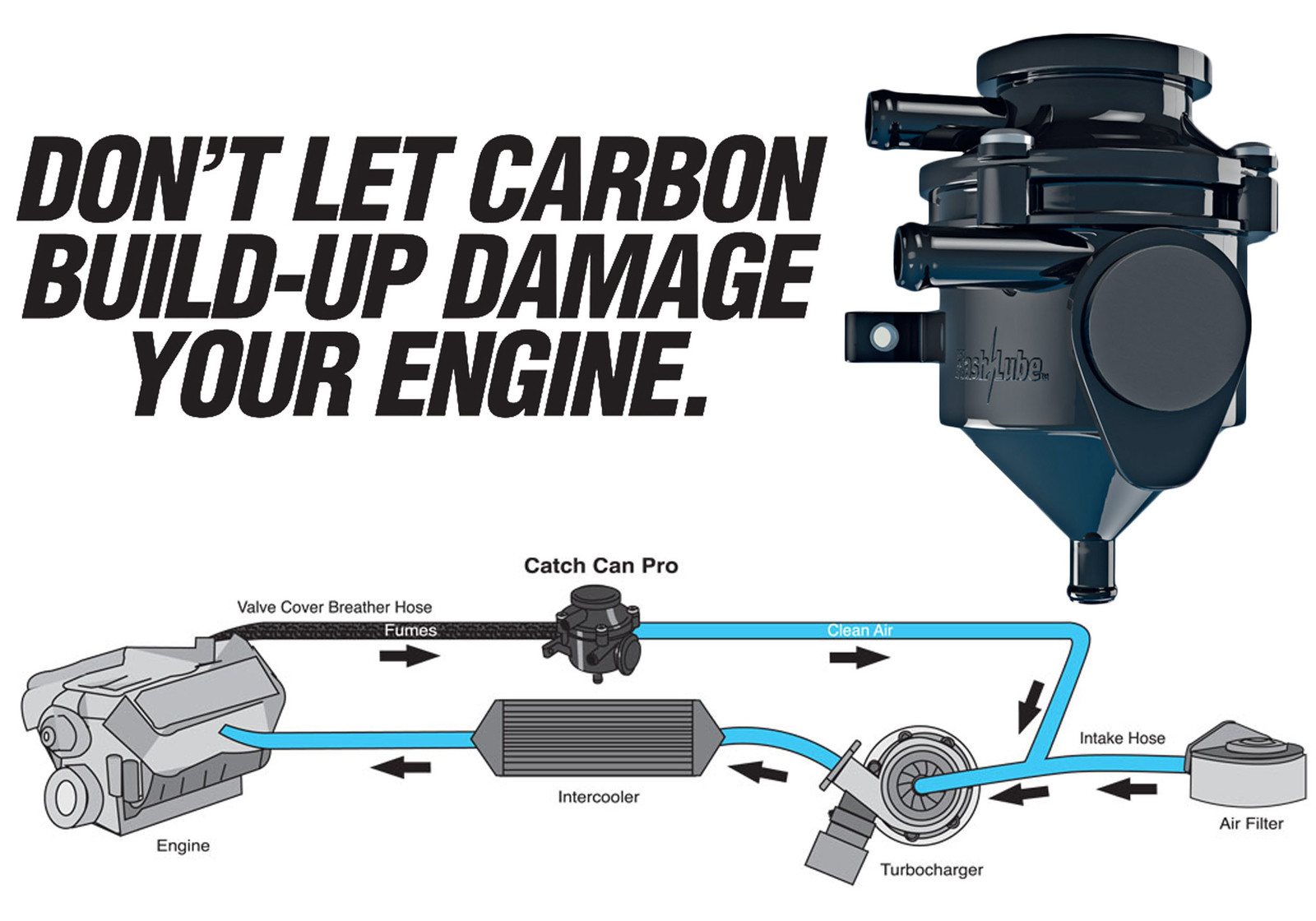

These engines typically vent the crankcase gases into the air intake, just after the air filter.

This feeds through the turbo and intercooler via the intake piping before entering the engine.

The turbo won't be much affected by a small amount of extra oil; the temperature a turbo runs at will keep the oil vaporised.

The intercooler is attempting to get the heat out of the intake air, and as temperature decreases, the oil mist creates droplets and sticks to the intercooler's internal surfaces.

It won't take long for a heavy breathing diesel engine to partially block the intercooler and inlet manifold sufficiently to provoke a loss in performance.

Another obstacle that will occur is with the Mass Air Flow (MAF) sensor, which regulates the fuel injection via the ECU.

A coating of dirty old oil doesn't allow the MAF sensor to read the airflow precisely, leading to incorrect fuelling and economy reduction.

If the MAF sensor is entirely out of its expected range, the ECU will implement limp-home mode, significantly reducing vehicle driveability.

Finding a suitable catch can to match the engine size is essential

When choosing a catch can, the most crucial task is ensuring the inlet and outlet hoses are the equivalent or larger diameter than the factory crankcase vent hoses it is replacing.

Some cans are one-size-fits-all solution, while others have a diversity of sizes, with sizing aligned to engine power.

A larger than necessary catch can has no disadvantages apart from the space required to fit it.

Flashlube, for example, reassure the consumer that even a well-worn LandCruiser 200 series won't overload the Catch Can Pro.

What makes a great catch can

As we mentioned, a catch can separates microscopic oil droplets from the crankcase air before the air is sent back to the engine via intake and the turbo.

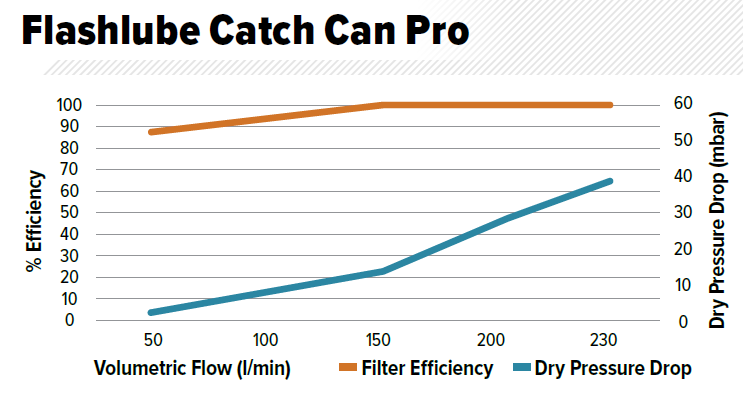

And of course, if a can is 0% effective, it means that it won't remove any oil from the air, while 100% effective removes all oil from the intake air.

Another consideration is the pressure drop. Air must be vented efficiently.

We can measure the change in pressure from the inlet to the outlet of the catch can.

Ideally, pressure on both sides of the catch can is even, meaning the air is crossing through without restriction, rather than building backpressure attempting to leak out upstream of the catch can and thus not flowing correctly.

The ideal catch can will have a 100% oil capture efficiency and zero pressure drop.

The Inlet Manifold Problem of Modern Diesel Engines

In this video, Brent from Terrain Tamer talks about Flashlube Catch Cans Pro

Most of today's diesel engines are turbocharged for better performance thus possibly creating more blow-by gases in the crankcase that escape via the PCV system.

This oily mist is redirected back into the inlet and can stick to the inside of the hoses, manifold and turbo turbine blades as well as the intercoolers.

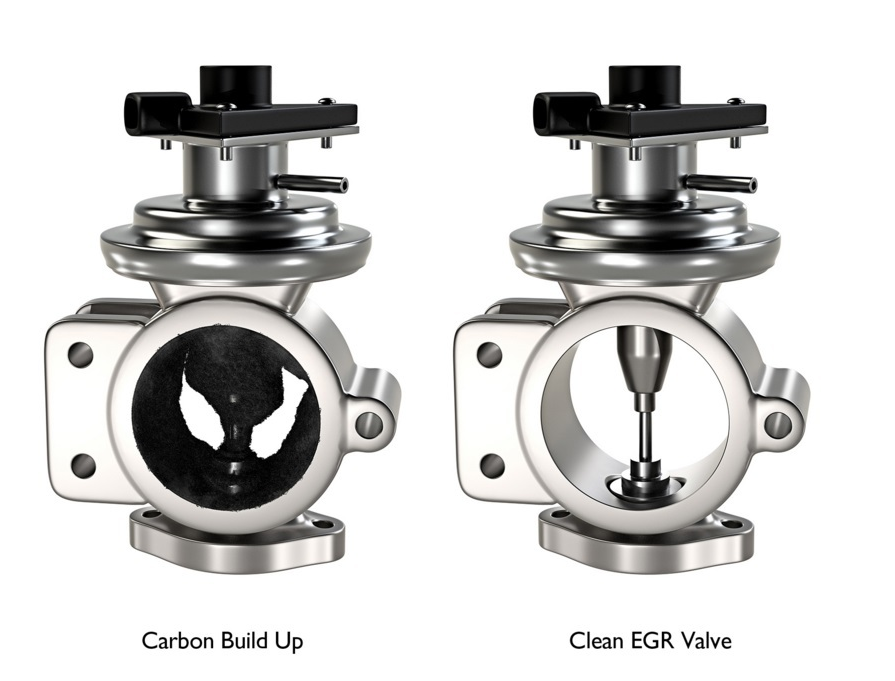

When soot-laden exhaust gas is introduced into the manifold as part of the EGR system, it can create a sticky mess that can dramatically restrict your manifold flow.

This build-up of soot and oil, together with the engine's heat, can bake on to the inlet manifold and eventually reduce the internal diameter of the inlet manifold.

Reducing Oil in the Inlet System

We recommend an oil mist separator's fitment or what is more commonly called a catch can to combat the build-up of oil from the crankcase ventilation system.

The catch can is a filter that sits between the outlet of the crankcase ventilation system, where it comes out from the valve cover, and the PCV valve where the mist is injected back into the air intake piping.

The catch can separates the oil from the air, and returns the oil-free air to the engine. The oil is then collected in a hose, a reservoir or plumbed back into the engine sump.

This reduces the oil in the intake system and leads to a cleaner engine burn and intake system.

Fitting a Catch Can to your Diesel Engine

At All Four X 4 in Kotara, we sell Flashlube Catch Can kits that come with everything you need to fit a catch can to your diesel engine.

Manufactured in Germany under licence, the Flashlube Catch Can kits are designed with unique safety valves to ensure their installation will not overpressurise the engine.

The kits are vehicle specific and include mounting bracket and the required hoses to connect the filter to your PCV valve and valve cover.

A general kit is also available to fit vehicles that do not have a specific kit available.

The kit comes with mounting bolts that fit existing threaded holes, so no drilling or threading is required.

The bracket in this kit mounts the catch can, close to the intake pipe and the PCV outlet on the motor's valve cover.

The moulded rubber hoses that come with the Flashlube kit are vehicle specific and therefore fit as required with minimal modifications to existing setups.

In this case, there is a hose from the valve cover outlet to the catch can inlet, and a second hose from the catch can outlet to the PCV valve on the intake hose of the engine, just before the turbo.

These hoses are secured by new hose clamps that are included as part of.

Another hose is fitted to the bottom of the catch can unit that will collect the oil that has been separated from the vapour.

This hose can be plumbed back into the engine's oil system using additional parts not supplied in the kit or used with the supplied tap valve allowing oil to be stored in the length of the hose.

If not being plumbed back into the engine's oil system, it is recommended that you empty the collected oil in the outlet hose monthly and/or at every service.

By reducing the oily mist entering your air intake, you reduce the build-up of sticky mess inside your turbocharger, inlet pipes, intercooler and inlet manifold.

This can help keep your diesel performing better.

How Flashlube Oil Catch Can Pro scored on Lab Tests

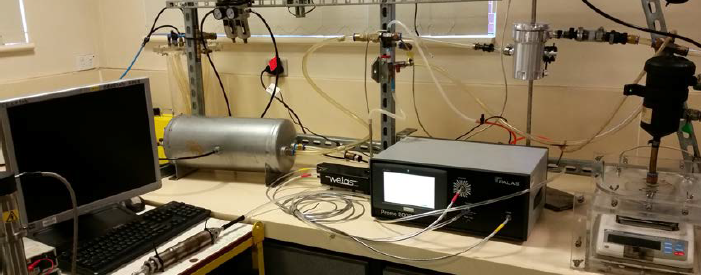

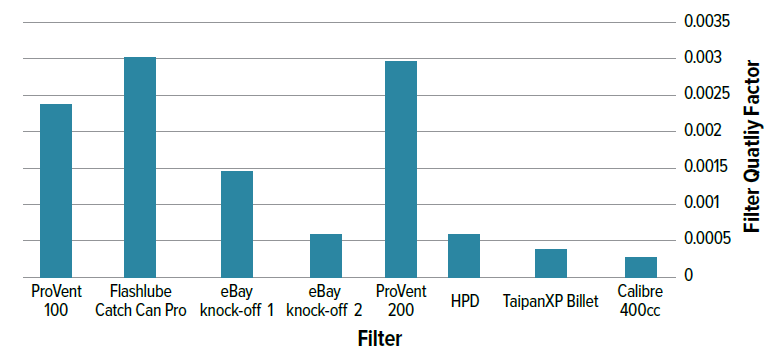

Recent studies conducted by Curtin University provided an efficiency and effectiveness score of some of the most commonly used catch cans brands in the market.

The testing method required drawing with a vacuum pump a measured airflow of 50-250 litres per minute through each catch can and then measuring their pressure before and after.

A good catch-can would have a high filtration efficiency and low-pressure drop, and Flashlube's Catch Can Pro scored the best across any competitors with the most effective filter efficiency at 150L/min

Credits: Unsealed 4X4 and Curtin University

Fitting and Recommendations

We would recommend having your inlet manifold professionally cleaned regularly to ensure it is free of oily build-up and soot from the EGR system.

This is a widespread issue in diesel engines, and performance can be severely affected if left without cleaning.

The Flashlube Catch Can kits can be ordered through our sales team for your specific vehicle and fitted yourself by following the included instructions.

Check our Flashlube page here. We also supply Flashlube Catch Can Pro Accessories and Spares such as Replaceable Serviceable Filter Elements suitable for Flashlube Catch Can Pro

Alternatively, our workshop team can fit the Flashlube Catch Can kit.

Conclusion

Do you have any questions? Contact our team today on (02) 4041 4000!